Top Hydraulic Recovery Winch Models for Heavy-Duty Towing

A hydraulic recovery winch is essential for towing and vehicle recovery in challenging conditions. Powered by hydraulic force, these winches deliver reliable and robust performance where electric winches might fail. In this article, we’ll look at the top hydraulic recovery winch models, their features, and their applications in various industries.

Key Takeaways

-

Hydraulic recovery winches utilize hydraulic power for heavy lifting and towing, offering advantages over electric winches in demanding conditions.

-

Key features to consider when selecting a hydraulic recovery winch include pulling power, durability, remote control options, and maintenance requirements.

-

Irun Winch is a leading supplier, offering a wide range of hydraulic winches with advanced features, showcasing a commitment to quality and industry standards.

Understanding Hydraulic Recovery Winches

A hydraulic winch recovery winch is a mechanical device that uses hydraulic power to pull or lift heavy loads, typically utilized in towing and recovery operations. These winches are designed for high-performance applications, offering powerful pulling capabilities without the electrical constraints of electric winches.

In vehicle recovery operations, hydraulic winches play a crucial role, providing the necessary power to recover vehicles stuck in mud, snow, or off-road situations. Hydraulic winches are particularly valuable in scenarios where traditional methods fail, ensuring timely recovery and reducing the risk of further damage to the vehicle.

They are especially effective in heavy-duty applications, making them essential for towing services that operate under demanding conditions. Understanding how these winches work and their advantages can help you appreciate their importance in various sectors.

Definition and Functionality

A hydraulic recovery winch is primarily designed to pull or lift heavy objects using pressurized hydraulic fluid to generate mechanical force. These winches are crucial in various sectors, including towing, construction, and forestry, where they provide significant pulling power. These winches leverage hydraulic power to tackle tasks requiring significant strength and dependability.

These winches are crucial for lifting, pulling, and tensioning heavy loads across various industries. They are particularly effective in vehicle recovery, construction, marine operations, and forestry. Their powerful towing capabilities make them indispensable in both heavy-duty and specialized applications.

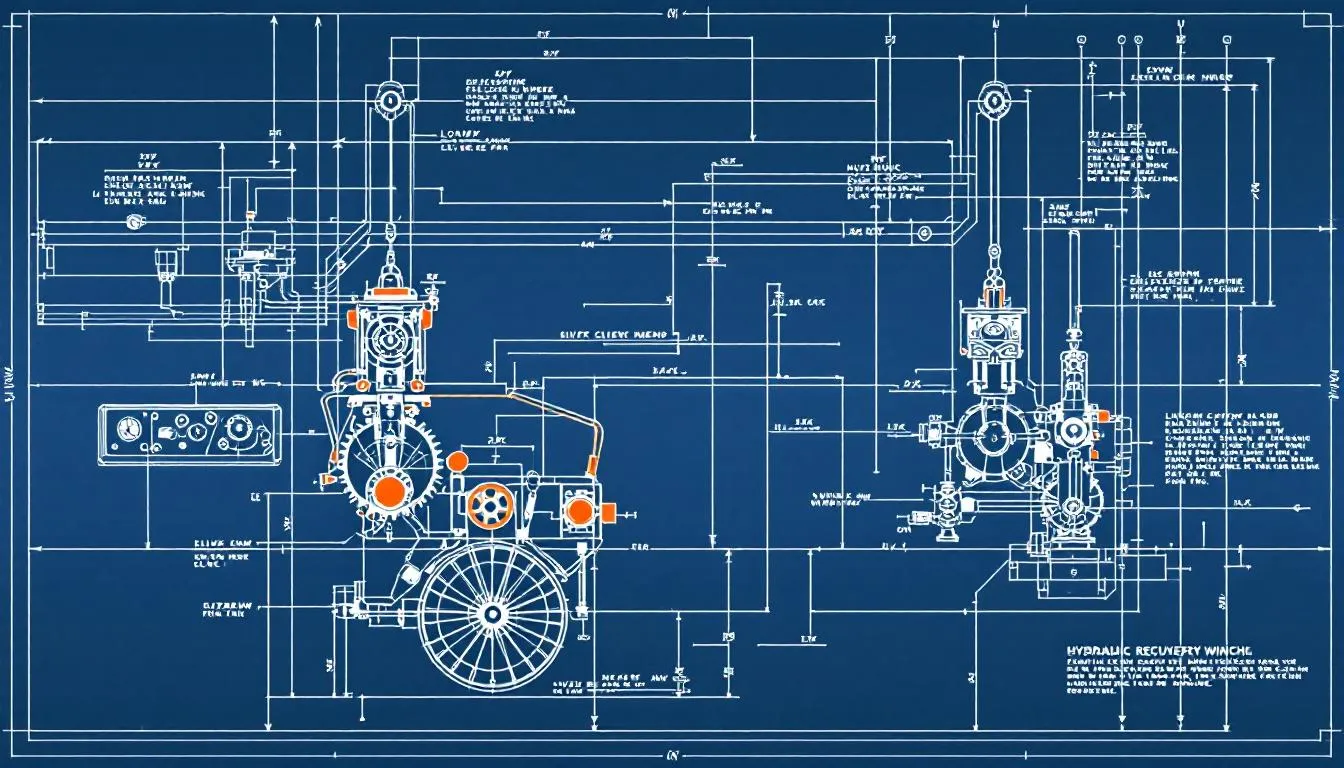

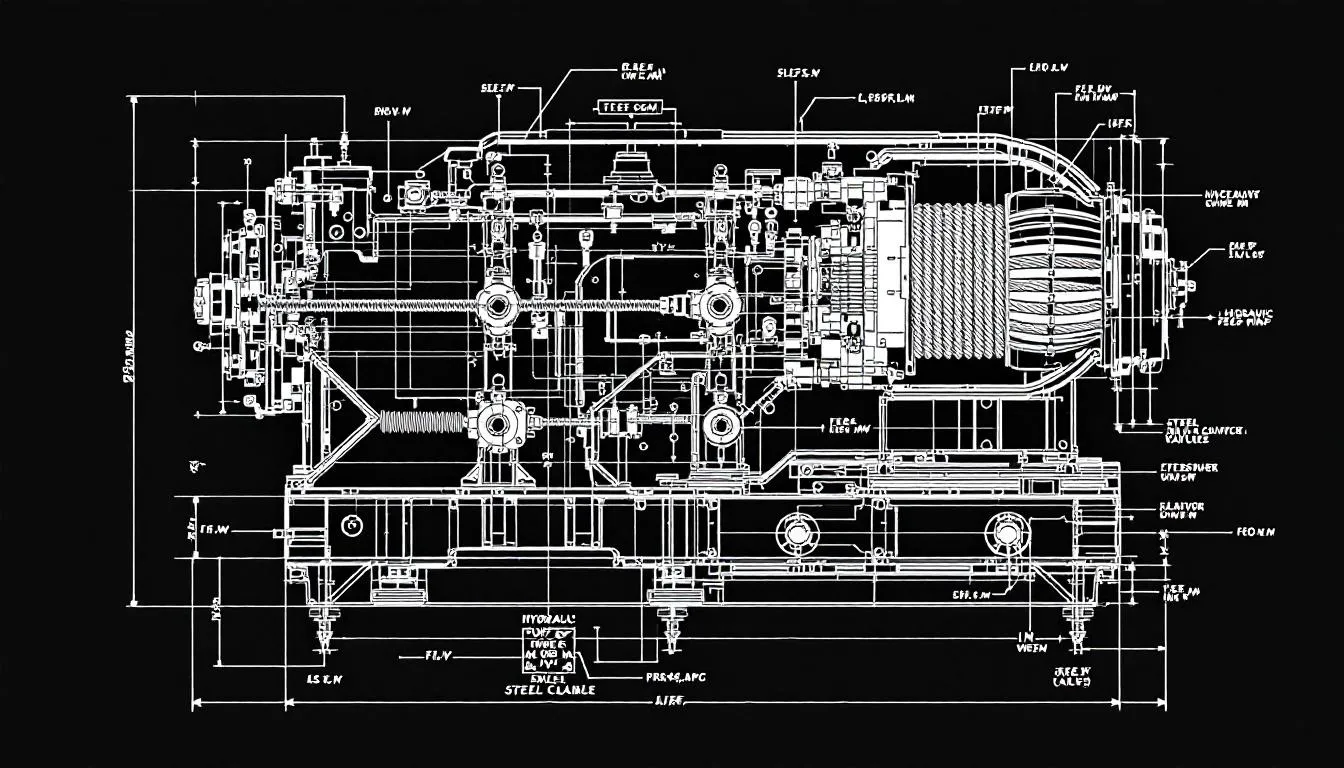

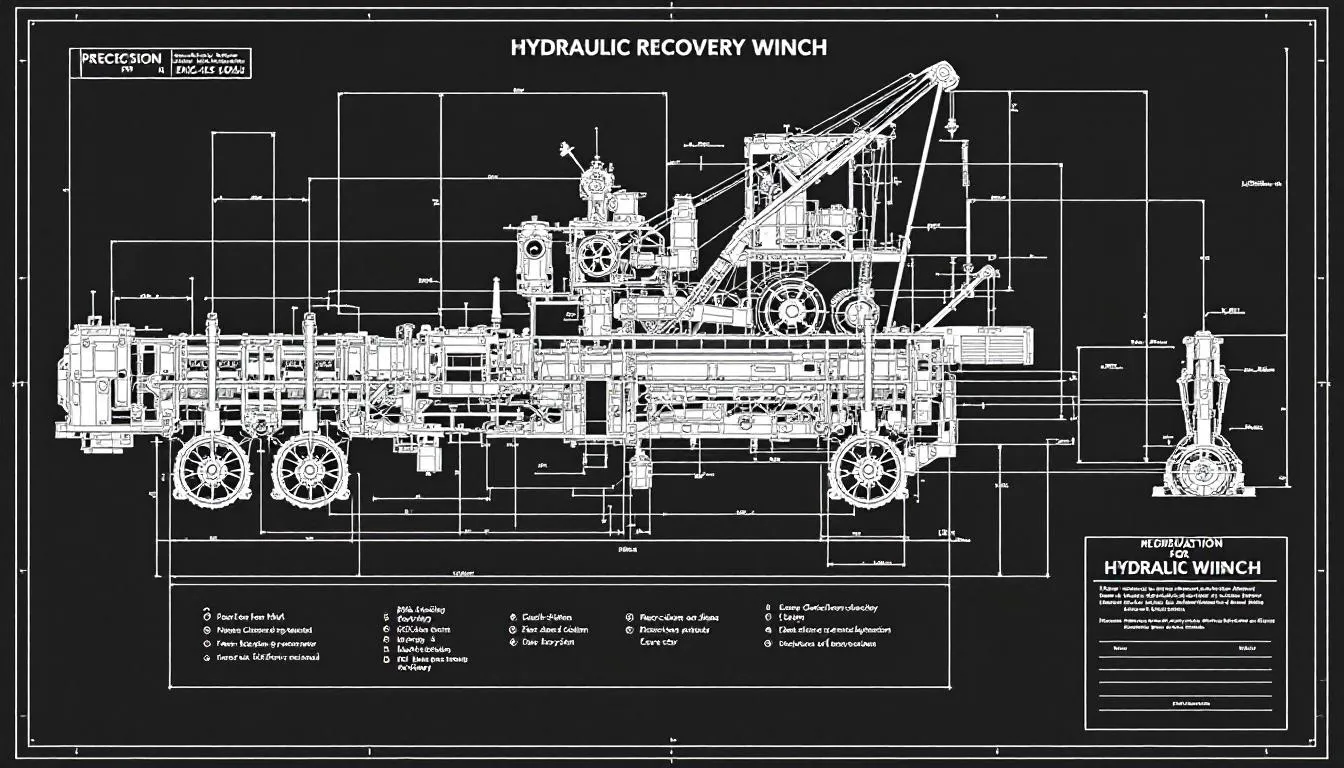

Key Components

Hydraulic recovery winches typically consist of a hydraulic motor, a series of gears, and a durable cable. Essential parts include a hydraulic pump, motor, winch drum, wire rope, and control valves that manage fluid flow. These components work together to provide the necessary pulling power for various tasks.

The winch drum is a critical component that holds and releases the cable during operation. Durable cables ensure safety and efficiency in lifting and towing tasks. The primary elements, including hydraulic motors, gears, and high-pressure hoses, facilitate the lifting and pulling process.

Advantages Over Electric Winches

Hydraulic recovery winches are praised for their power and efficiency, making them ideal for heavy-duty towing applications. They offer significant pulling power and reliability compared to other winch types. This makes them essential for operations that require consistent and robust performance.

These winches offer several advantages over electric winches, particularly in heavy-duty towing applications. Their ability to operate without electrical constraints ensures continuous and efficient operation, even in the most demanding conditions.

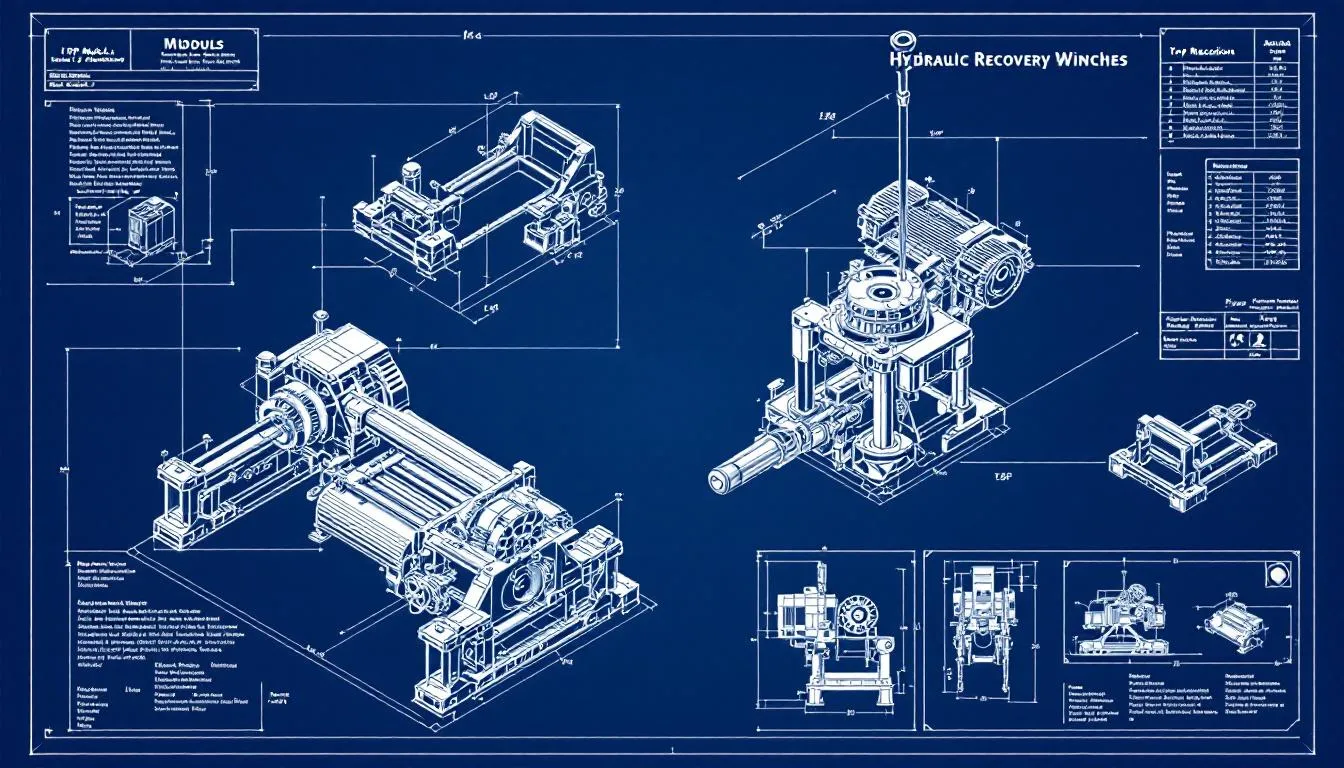

Top Models of Hydraulic Recovery Winches

When selecting a hydraulic recovery winch, it’s crucial to consider models that offer optimal performance for vehicle recovery operations. The right model can make a significant difference in efficiency and reliability. We will examine three top models, each offering unique features and benefits.

Model A features a powerful hydraulic system, robust build quality, and capacity suited for heavy-duty applications. Model B is known for its exceptional durability and has received excellent user feedback for its reliability during rigorous pulling tasks, highlighting the planetary change in performance expectations.

Model C is competitively priced, providing a strong value proposition thanks to positive customer reviews regarding its efficiency and effectiveness.

Model A: Specifications and Features

Model A has the following features:

-

Pulling capacity of up to 20,000 pounds, suitable for heavy-duty towing operations

-

Hydraulic system capable of operating at pressures of 3,000 PSI, ensuring high efficiency and reliability

-

Equipped with a 15-foot hydraulic hose

-

Comes with a rugged steel frame for enhanced durability

Model A includes a remote control for convenient operation from a distance. It is designed with a built-in safety shutoff feature to prevent overheating, enhancing user safety. This model excels in environments where electric winches may fail, making it ideal for off-road recovery, construction, marine, and forestry applications.

Model B: Performance and Durability

Users report that Model B offers:

-

Superior performance in extreme conditions, demonstrating high resistance to wear and tear.

-

Consistent performance even after extensive use in harsh conditions.

-

Robust construction, providing a long lifespan even under challenging conditions.

User feedback indicates that Model B excels in both performance and durability, making it a reliable choice for heavy-duty towing. Its durable build resists wear and tear, ensuring longevity in demanding applications.

Model C: Price and Value

Model C’s price point positions it as a strong contender in the market for both hobbyists and professionals. It is competitively priced, offering a good balance of performance and affordability for budget-conscious buyers.

The strong performance combined with its price makes Model C appealing to a wide range of customers.

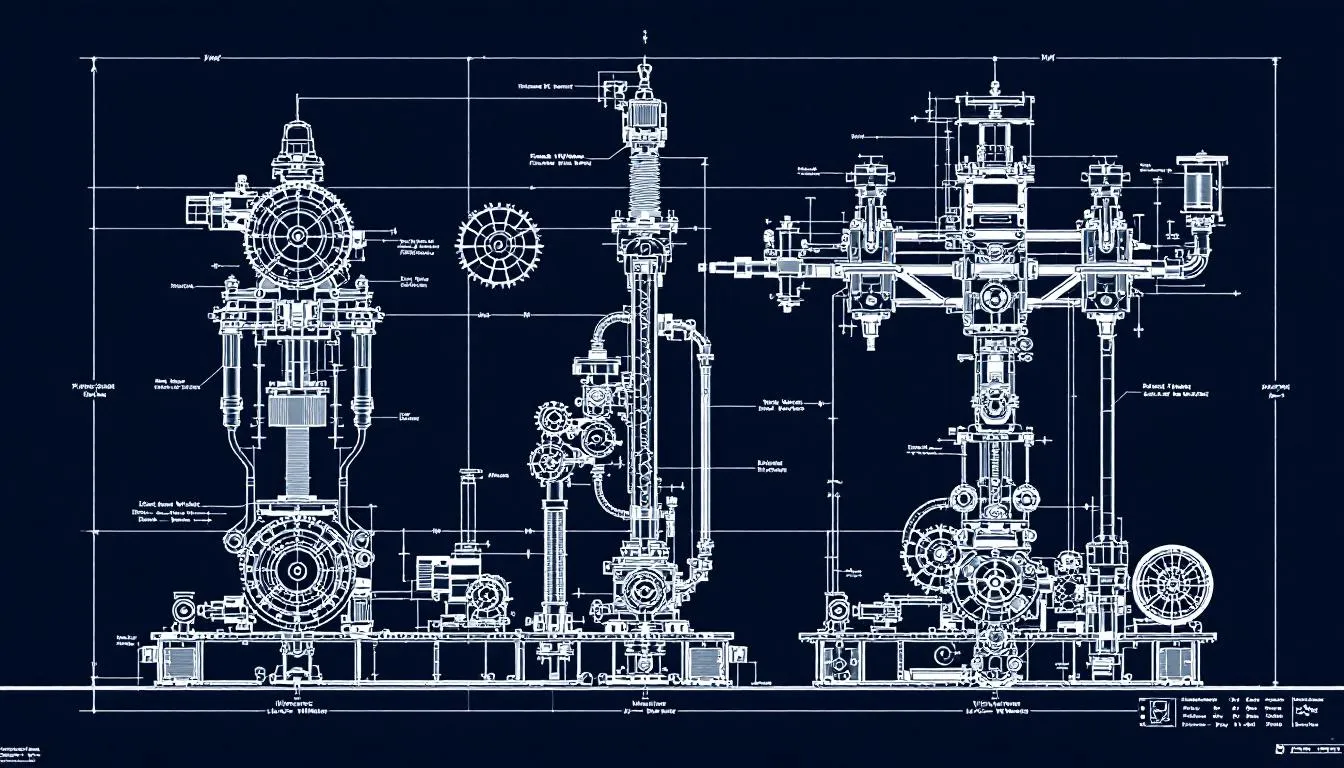

Industrial and Commercial Applications

Hydraulic recovery winches are vital tools for safely recovering vehicles that are stuck or overturned. They utilize hydraulic power to perform heavy lifting and towing tasks, making them indispensable in vehicle recovery scenarios. These winches are engineered to facilitate vehicle recovery in various challenging scenarios.

Hydraulic winches also play a crucial role in other industrial and commercial applications, including construction sites, marine, and forestry operations. Their ability to handle heavy loads and operate in harsh environments makes them versatile and reliable tools for many industries.

Vehicle Recovery

Hydraulic winches are often used in vehicle recovery to extract stuck vehicles from challenging terrains, ensuring safe and efficient recovery. These winches utilize hydraulic power to pull heavy loads, making them more efficient for recovery tasks compared to traditional methods.

A hydraulic recovery winch is designed to pull heavy loads using hydraulic power, making it effective for recovering vehicles stuck in challenging terrains like mud or snow. The pulling power of hydraulic recovery winches can reach up to 15,000 lbs, making it essential to choose one that meets specific recovery needs.

Construction Sites

Hydraulic winches play a critical role on construction sites, significantly improving operational workflows. They assist in lifting and moving heavy materials like steel beams and concrete blocks, enhancing safety and efficiency in demanding operations.

Utilizing hydraulic winches improves safety in demanding operations while also enhancing overall efficiency.

Marine and Forestry Applications

Hydraulic winches made from high-quality materials typically offer better resistance to corrosion and extend the lifespan of the equipment in harsh conditions. These winches are designed to withstand harsh environments, making them resistant to corrosion and able to operate effectively in extreme conditions.

The materials used in hydraulic recovery winches contribute significantly to their durability and effectiveness in marine and forestry operations. Hydraulic recovery winches are essential in marine and forestry applications due to their ability to operate in challenging conditions.

Key Features to Look for in a Hydraulic Recovery Winch

Selecting a hydraulic recovery winch involves evaluating several critical features that ensure optimal performance and reliability. Proper installation is critical for ensuring a hydraulic recovery winch operates safely and effectively, preventing potential hazards and equipment failures. Using high-strength Grade 8 hardware for mounting the winch is crucial to withstand the forces exerted during operation.

Routine maintenance for hydraulic systems includes:

-

Regularly checking hydraulic fluid levels.

-

Inspecting hoses and seals for leaks or damage.

-

Specifically for hydraulic winches, monitoring the hydraulic fluid level and inspecting hoses for leaks or damage.

-

Regularly inspecting hydraulic hoses for wear to prevent potential failures and leaks.

Pulling Power and Capacity

Hydraulic winches typically offer higher pulling power and durability compared to electric winches, making them more suitable for heavy-duty tasks. They generally provide greater pulling strength and can operate continuously without overheating compared to electric models.

When selecting a hydraulic recovery winch, consider its ability to provide consistent pulling force and efficient operation. Model A offers the following features:

-

8,000 lbs (3,636 kg) rated capacity

-

Internal drag brakes to minimize back spinning

-

Advanced hydraulic technology to enhance lifting capabilities and speed.

Remote Control and Ease of Use

Many hydraulic recovery winches come equipped with remote control options, enhancing user convenience and allowing for easy operation from a quick safe distance. Wireless remote controls significantly enhance user convenience, allowing for operation from a safe hand distance during recovery tasks.

Remote control features allow users to operate the winch easily, enhancing safety during operations.

Durability and Corrosion Resistance

Model A features a robust construction that ensures reliable performance in challenging environments. Using high-strength Grade 8 hardware for mounting the winch is crucial to withstand the forces exerted during operation.

Regularly inspecting hydraulic hoses for wear can prevent potential failures and leaks.

Installation and Maintenance Tips

Proper installation ensures that the hydraulic recovery winch operates effectively and reduces the risk of future maintenance issues. Ensuring the cleanliness and quality of hydraulic oil is vital for the efficient operation of hydraulic recovery winches. For hydraulic winches, regularly monitor the hydraulic fluid level and inspect hoses for leaks or damage.

Manufacturers generally offer dedicated customer service lines and online resources to assist users with installation and operation. Regular maintenance is vital for ensuring optimal performance and longevity. Regularly checking hydraulic fluid levels and inspecting hoses and seals is necessary for routine maintenance.

Installation Guidelines

Proper installation of a hydraulic recovery winch begins with correct preparation of the winch line, ensuring smooth and efficient operation. Frequent binding of the winch line during operation often results from improper spooling or tension when initially winding the line onto the drum.

Manufacturers typically provide dedicated customer service lines and online resources to assist users with installation and operation of winches. Securely mounting the winch in place is crucial to prevent movement during operation and avoid potential damage.

Ensuring all necessary safety precautions are taken before the winch is operated is also crucial.

Regular Maintenance Practices

Regular maintenance is vital for ensuring optimal performance and longevity. Checking and replacing the hydraulic fluid at regular intervals is essential for maintaining winch efficiency. Routine inspections should be performed on hydraulic recovery winches to identify wear and potential issues before they escalate.

Customer service often includes troubleshooting assistance and guidance on installation and operational best practices. Manufacturers usually provide a range of support services, including documentation, troubleshooting guides, and direct customer service.

Regularly checking and changing hydraulic fluid is necessary for maintaining system performance and longevity. Regularly inspecting hydraulic hoses for wear can prevent potential failures and leaks.

Troubleshooting Common Issues

Common problems users face with hydraulic winches include:

-

Hydraulic fluid leaks, which can occur due to damaged hoses or fittings.

-

Engine malfunctions.

-

Issues with the winch cable. Inspecting the winch cable regularly can help identify wear and tear, preventing potential failures during use.

For engine malfunctions, check the hydraulic fluid level, ensure there are no obstructions in the system, and confirm that the engine is receiving the appropriate power supply.

Support and Warranty Information

Many manufacturers offer technical support through various channels, including phone, email, and online resources, to assist customers with winch-related inquiries. Hydraulic recovery winches often include a user manual detailing support options and warranty terms. Manufacturer support is crucial for ensuring users of hydraulic recovery winches receive the assistance they need for optimal operation.

Warranty coverage for hydraulic winches commonly includes:

-

Duration: typically lasts between one to five years, depending on the manufacturer and specific product models.

-

Standard warranty: covers defects in materials and workmanship for a specified period.

-

Exclusions: normal wear and tear is usually not covered.

-

Extended warranties: provide additional coverage beyond the standard warranty, often including parts and labor for repairs.

Manufacturer Support

Manufacturers often provide customer service through various channels, including phone support, online chat, and email, to assist users with product-related inquiries. Most manufacturers offer dedicated customer service lines for technical assistance and troubleshooting related to hydraulic recovery winches. This support is crucial for ensuring users receive the assistance they need for optimal operation.

Warranty Coverage

Warranty coverage for hydraulic recovery winches commonly spans from 3 to 7 years, depending on the model and its intended usage. The standard warranty typically covers defects in materials and workmanship for a specified period, but excludes normal wear and tear.

Extended Warranty Options

Purchasing an extended warranty for hydraulic recovery winches can provide additional coverage beyond the standard warranty, often including parts and service. Many manufacturers offer extended warranty plans that can provide additional coverage beyond the standard warranty, often including benefits such as extended service periods and lower repair costs.

Recommend the Leading Hydraulic Recovery Winch Supplier - Irun Winch

When it comes to selecting a reliable supplier to find hydraulic recovery winches, Irun Winch stands out as a leader in the industry. ZHEJIANG JINHUA RUNYE TECH. CO., LTD. (Irun) specializes in developing and manufacturing vehicle winches and off-road accessories suitable for ATVs, UTVs, 4x4 vehicles, wreckers, flat-plate hauling vehicles, engineering machinery, off-road military vehicles, and specialty vehicles.

As the pioneer professional manufacturer of vehicle winches, Irun has one of the biggest winch R&D and production bases in China, with a factory covering a gross production floor area of approximately 9,746.1 square meters and an annual production capability of 200,000 winches.

Irun’s product range consists of more than 100 models, including electric and hydraulic winches with pulling power from 2,000 lbs to 50,000 lbs. They emphasize product details development and quality, holding ISO 9001:2000 certification and CE and ROHS certifications for their products, allowing customers to select the best options.

The company takes integrity as its business philosophy and is dedicated to providing high-quality products and services to customers and society.

Summary

Hydraulic recovery winches are essential tools for heavy-duty towing and recovery operations. They offer significant advantages over electric winches, including higher pulling power, efficiency, and reliability. By understanding the key components, advantages, and applications of hydraulic winches, you can make an informed decision when selecting the right model for your needs.

As we’ve explored, top models like Model A, Model B, and Model C each offer unique features and benefits. Additionally, proper installation, regular maintenance, and understanding warranty options are crucial for ensuring optimal performance and longevity. For those looking for a trusted supplier, Irun Winch stands out for its commitment to quality and customer satisfaction. Invest in a hydraulic winch today and experience the power and reliability these incredible machines have to offer.

Frequently Asked Questions about Hydraulic Recovery Winch

What is a hydraulic recovery winch?

A hydraulic recovery winch is a powerful tool that utilizes hydraulic power to effectively pull or lift heavy loads, making it ideal for towing and recovery operations. This device enhances efficiency and safety in challenging recovery scenarios.

What are the advantages of hydraulic winches over electric winches?

Hydraulic winches provide greater pulling power and efficiency compared to electric winches, making them more reliable for heavy-duty applications. This robustness is essential for tasks requiring significant strength and durability.

What are the key components of a hydraulic recovery winch?

The key components of a hydraulic recovery winch are the hydraulic motor, gears, winch drum, wire rope, hydraulic pump, and control valves for fluid management. These elements work together to ensure efficient operation and recovery.

How do I maintain my hydraulic recovery winch?

To maintain your hydraulic recovery winch, regularly check and replace the hydraulic fluid, inspect hoses and seals, and conduct routine inspections to identify wear or potential issues early. This proactive approach will ensure optimal performance and longevity of your equipment.

Why should I choose Irun Winch as my supplier?

Choosing Irun Winch as your supplier ensures access to high-quality products backed by strong manufacturing capabilities and a commitment to customer satisfaction. Their diverse model range and focus on product development further solidify their reputation as a dependable partner.