Choosing the Best Hydraulic Winch for Wreckers: A Comprehensive

Struggling to find the best hydraulic winch for wreckers? This guide will walk you through the benefits of hydraulic winches, key features to consider, and common issues to avoid.

Key Takeaways

-

Hydraulic winches provide superior performance, durability, and reliability compared to electric winches, making them preferable for heavy-duty towing operations.

-

Key factors for selecting a hydraulic winch include pulling capacity, gear ratio, and cable material, ensuring the winch meets specific towing requirements.

-

Regular maintenance, compliance with safety standards, and operator training are essential for the effective operation and longevity of hydraulic winches.

Understanding Hydraulic Winches for Wreckers

Hydraulic winches are vital in the towing industry, providing the necessary power to lift and pull vehicles with efficiency and reliability. Unlike electric winches, which can overheat and require frequent maintenance, hydraulic winches offer superior performance and durability, making them the preferred choice for heavy-duty towing operations.

These winches must adhere to stringent national safety standards, including those set by organizations like OSHA. Compliance with these regulations not only ensures the legality of operations but also significantly reduces the risks associated with towing activities.

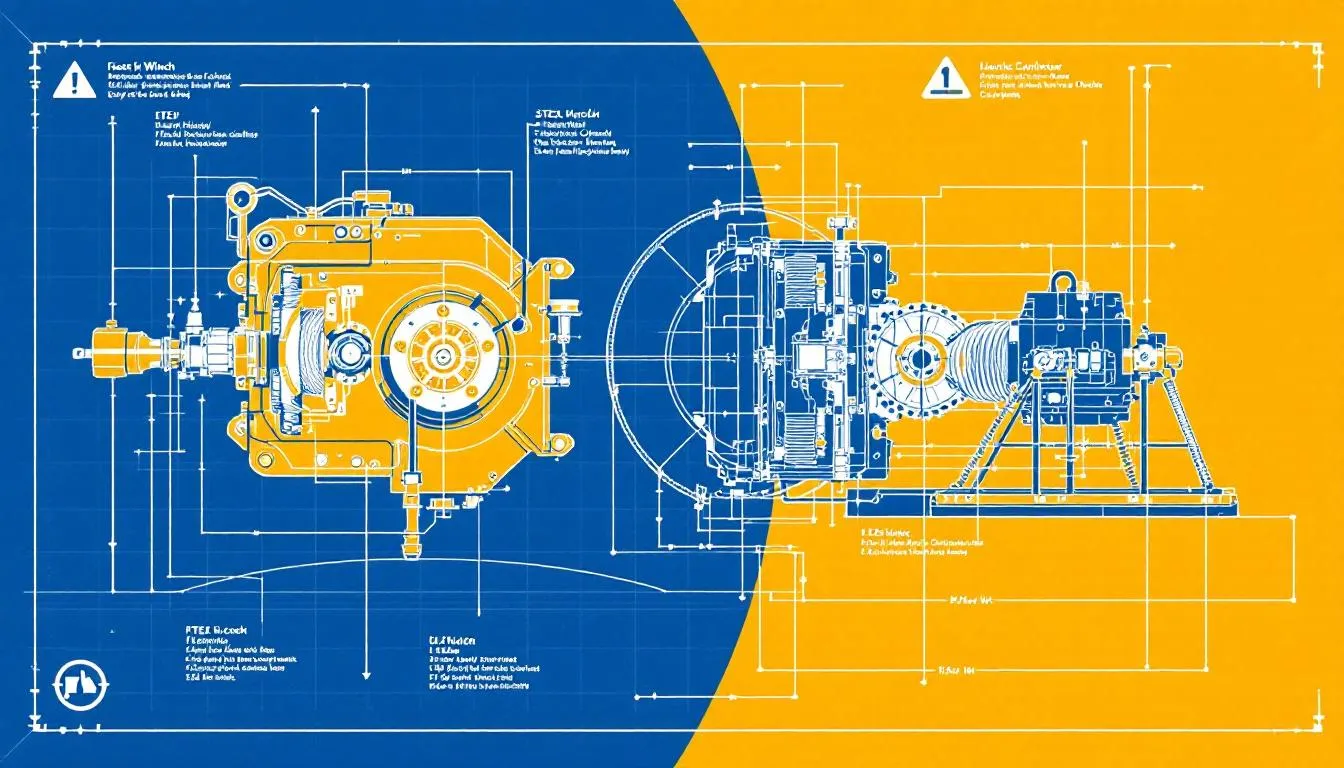

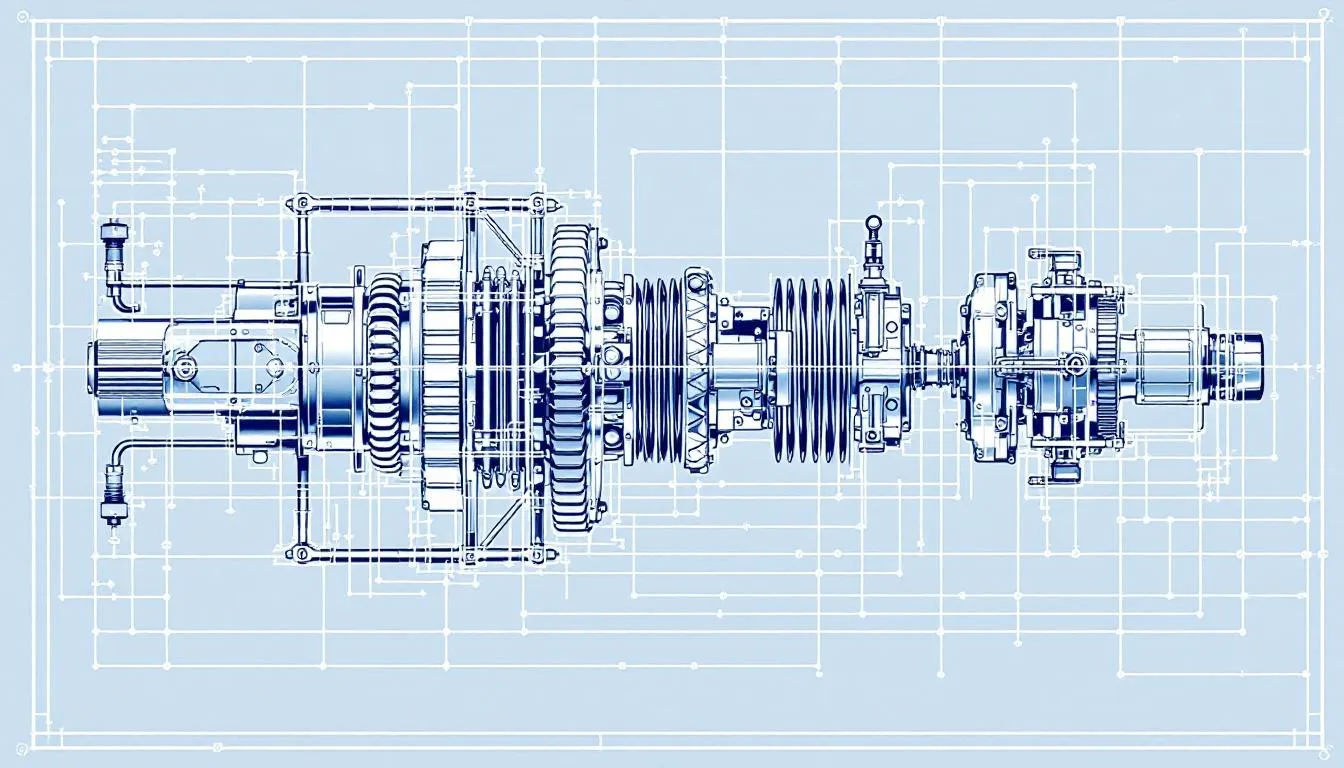

Basics of Hydraulic Systems

Grasping the fundamentals of hydraulic systems helps in understanding the operation of hydraulic winches. At their core, hydraulic systems use pressurized fluid to generate mechanical force, enabling heavy lifting and pulling tasks that would be impossible with manual effort.

These systems consist of several key components, including:

-

a motor

-

pump

-

reservoir

-

valves

-

hoses

The pump draws low-pressure fluid from the reservoir and converts it into high-pressure fluid, which is then directed by valves to perform work.

This high-pressure fluid powered the hydraulic motor, which in turn drives the winch drum, allowing it to pull heavy loads with ease.

Advantages of Hydraulic Winches

Hydraulic winches offer several advantages over their electric counterparts, making them an ideal choice for wreckers:

-

Greater pulling strength

-

Consistent performance, even under demanding conditions

-

High torque capacity that allows them to handle heavier loads, which is essential in towing operations.

Moreover, hydraulic winches are known for:

-

Superior reliability and lower maintenance requirements.

-

Consistent power output from hydraulic systems, resulting in smoother operation and reduced wear on components.

-

Ensuring a longer lifespan for the winch.

-

Providing precise control over speed and force, which is vital for delicate recovery operations.

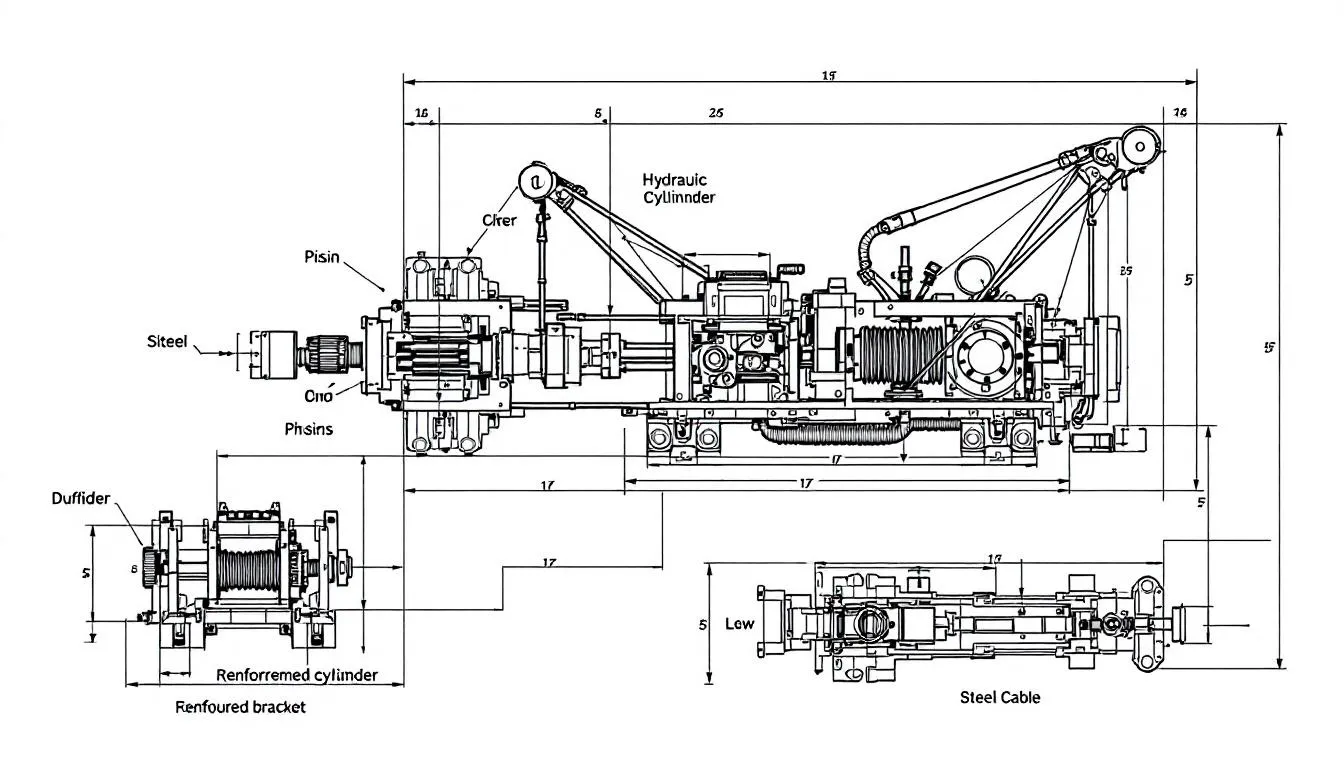

Key Features to Consider When Choosing a Hydraulic Winch

Selecting the right hydraulic winch involves evaluating several key features that can significantly impact its performance and engage suitability for your specific towing needs.

These features include pulling capacity, gear ratio, and the type of winch cable used.

Pulling Capacity

The pulling capacity of a hydraulic winch is one of the most critical factors to consider. This capacity must exceed the maximum weight of the loads you plan to handle, ensuring that the winch can perform efficiently under all conditions. Hydraulic winches leverage pressurized fluid to generate high pulling power, making them essential for towing heavy loads.

Choosing a winch with the appropriate pulling capacity not only enhances performance but also ensures the safety and reliability of your operations. For instance, if you frequently tow heavy vehicles, opting for a winch with a higher pulling capacity will prevent overloading and potential equipment failure.

Gear Ratio and Speed

The gear ratio of a hydraulic winch plays a pivotal role in determining its operational speed and power. A higher gear ratio means more pulling power but slower speed, while a lower gear ratio provides faster operation but less torque. Balancing these factors is crucial for specific recovery tasks, as the right gear ratio will ensure efficient and effective performance.

For example, a winch with a planetary gear system might be chosen for its balance between speed and power, making it suitable for a variety of towing scenarios. In contrast, a winch with a worm gear system might be selected for its high torque capacity, ideal for heavy-duty recovery operations.

Cable Options: Steel vs. Synthetic Rope

When selecting a hydraulic winch, the choice of winch cable is another crucial consideration. Steel cables are known for their strength and durability, making them suitable for heavy loads and extreme conditions. However, they are heavier and can be more challenging to handle.

On the other hand, synthetic ropes offer unique advantages such as being lighter and more flexible, which makes them easier to handle and safer in the event of a break. While synthetic ropes provide these safety benefits, steel cables have greater abrasion resistance, making them more suitable for rough environments.

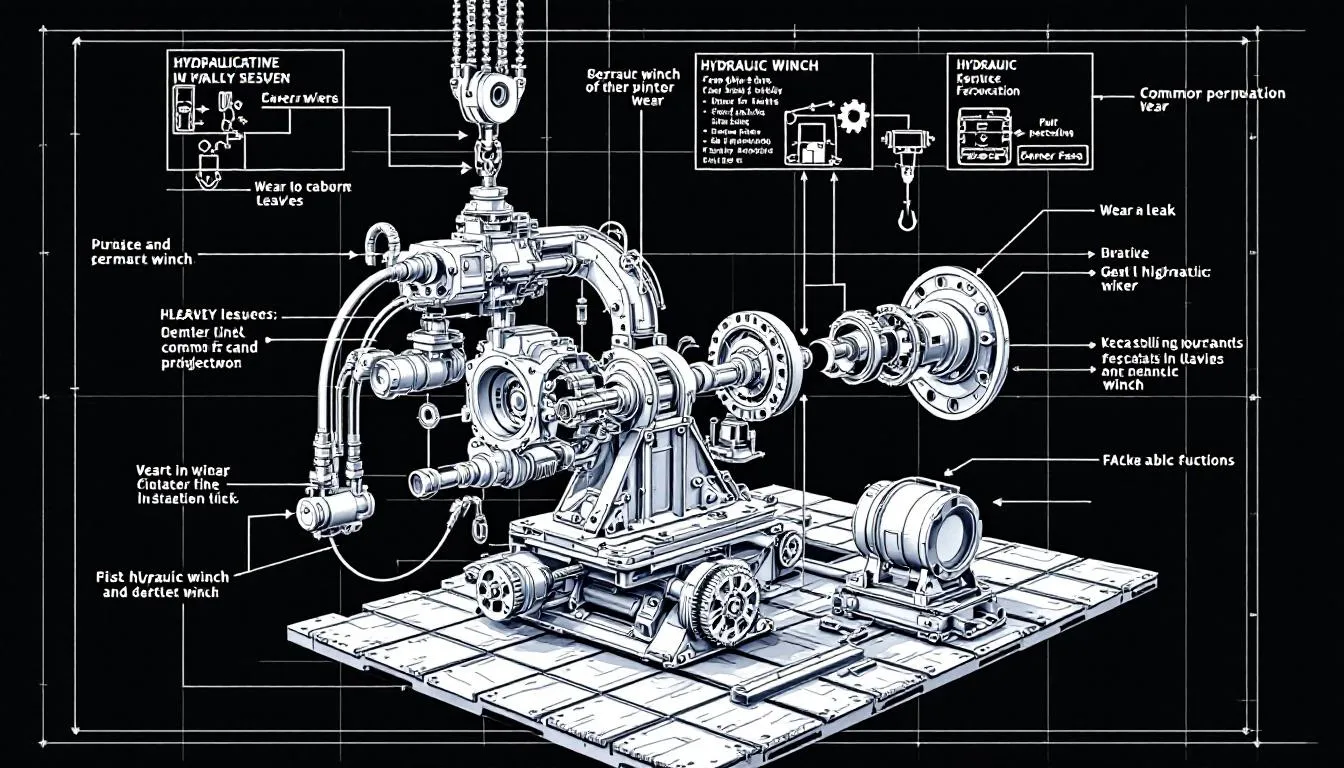

Common Issues with Hydraulic Winches and How to Fix Them

Despite their robustness, hydraulic winches can encounter several common issues that may impact their performance. These problems often stem from factors such as seal failures, contamination, and incorrect installation.

Regular maintenance and checks can prevent most of these issues, ensuring that your winch operates efficiently and is ready for repair.

Hydraulic Leaks

Hydraulic leaks are a common issue that can significantly affect the efficiency of a winch. These leaks often result from deteriorating seals, loose fittings, or damaged hoses, necessitating regular inspections to prevent fluid loss. Wear and tear on high-pressure hoses can lead to significant oil leaks, posing environmental and safety risks.

Mitigating these risks involves:

-

Ensuring correct installation of the hydraulic system

-

Using quality hydraulic fluids

-

Regularly inspecting seals and hoses for wear

-

Maintaining tight and secure connections to prevent leaks and maintain the winch’s performance.

Brake Malfunctions

Brake malfunctions in hydraulic winches can lead to significant performance issues and safety hazards. Common brake problems include complete brake failure, which can result in loss of control during towing operations. Brake wear or improper adjustment can also reduce the winch’s ability to stop or hold a load securely.

Checking hydraulic fluid levels and inspecting brake components for wear regularly are key troubleshooting steps. Promptly addressing brake malfunctions ensures the longevity and effective performance of hydraulic winches.

Electrical Failures in Hydraulic Winches

Electrical failures in hydraulic winches often stem from loose connections, faulty wiring, or issues with power sources. These problems can lead to operational inefficiencies and even complete winch failure if not addressed promptly.

Preventing electrical issues involves:

-

Keeping connections clean and secure

-

Inspecting the battery for proper charge and performance

-

Regularly checking and replacing faulty wiring connections to maintain the winch’s operational efficiency.

Maintenance Tips for Hydraulic Winches

Maintaining hydraulic winches properly is key to their optimal performance and longevity. Regular inspections, proper lubrication, and cable care are all crucial aspects of maintaining these powerful tools.

Regular Inspections

Inspecting hydraulic winches regularly helps identify potential issues early, reducing the risk of major failures. Consistent checks on winches can help identify issues like wear, fluid levels, and structural integrity early on.

Local and federal laws often mandate regular safety inspections for winches and tow trucks to ensure they meet safety standards. To minimize the risk of hydraulic leaks, ensure that the hydraulic system is installed correctly and regularly inspect seals and hoses for wear.

Proper Lubrication

Lubricating moving parts minimizes friction and wear, significantly enhancing winch performance. Using high-quality lubricants specifically designed for hydraulic systems can improve performance and extend the lifespan of components.

Cable Care and Storage

Maintaining winch cables properly ensures their longevity and optimal performance during towing operations. Regularly inspect cables for signs of wear, frays, or other tangled damage to prevent failures.

Store cables properly on a dedicated reel or in a protective case to avoid kinks and damage. Proper cable care not only ensures reliable performance but also extends the life of the winch cable.

Compliance and Safety Standards for Hydraulic Winches

Adhering to safety standards is essential for the safe and legal operation of hydraulic winches. Built-in safety features, such as overload protection, enhance operational safety during use.

Understanding Relevant Regulations

Hydraulic winches and towing operations must comply with local, state, and federal regulations to ensure safety and legal operation. Operators should undergo training and certification to manage equipment safely and operate in adherence to regulations.

Accurate records of maintenance, inspections, and compliance checks are vital to add demonstrating adherence to regulations in hydraulic winch operations over time.

Training and Certification Requirements

Training operators properly is crucial for the safe use of hydraulic winches and avoiding accidents during towing operations. When using gear such as D-rings or bow shackles with a winch, operators should ensure that the gear is rated for the load and check all connections before winching.

Record Keeping for Compliance

Keeping records of inspections and maintenance is crucial for compliance audits and ensuring operational safety. Detailed records of maintenance and inspections are crucial for proving compliance with regulatory bodies.

Recommend the Leading Hydraulic Winch for Wreckers Supplier - Irun Winch

For those in search of a reliable supplier of hydraulic winches for wreckers, Irun Winch stands out as a leading choice. ZHEJIANG JINHUA RUNYE TECH. CO.,LTD. (Irun) specializes in developing and manufacturing vehicle winches and off-road accessories suitable for a wide range of vehicles, including:

-

ATVs

-

UTVs

-

4x4 vehicles

-

Wreckers

-

Flat-plate hauling vehicles

-

Engineering machinery

-

Off-road military vehicles

-

Specialty vehicles.

As a pioneer in the industry, Irun Winch boasts one of the largest winch R&D and production bases in China, with a factory covering approximately 9,746.1 square meters and an annual production capability of 200,000 winches. Their product range includes more than 100 models, with pulling power from 2,000 to 50,000 pounds, ensuring a solution for virtually any towing need.

Summary

Choosing the right hydraulic winch for wreckers involves evaluating several key features, understanding common issues and their solutions, and adhering to maintenance and safety standards. By focusing on pulling capacity, gear ratio, and cable options, you can ensure that your winch meets the demands of your towing operations.

In conclusion, investing in a high-quality hydraulic winch and maintaining it properly will enhance the efficiency and safety of your towing activities. With the right knowledge and tools, you can tackle any towing challenge with confidence and ease.

Frequently Asked Questions about Hydraulic Winch for Wreckers

What is the main advantage of using hydraulic winches over electric winches?

The main advantage of hydraulic winches over electric winches is their greater pulling strength and reliability, allowing them to handle heavier loads with consistent performance and reduced maintenance requirements.

How often should hydraulic winches be inspected?

Hydraulic winches should be inspected regularly to identify potential issues and ensure safety standards are met. Consistent checks help detect wear, fluid levels, and maintain structural integrity.

What are the common causes of hydraulic leaks in winches?

Hydraulic leaks in winches commonly occur due to deteriorating seals, loose fittings, and damaged hoses. Regular inspections and the use of quality hydraulic fluids are essential to prevent these issues and ensure optimal performance.

Why is proper training important for operators of hydraulic winches?

Proper training is crucial for hydraulic winch operators as it equips them with the knowledge to operate the equipment safely, minimizing the risk of accidents and ensuring compliance with regulations. This training not only protects the operators but also enhances the overall safety and efficiency of operations.

What should be considered when choosing between steel cables and synthetic ropes for winches?

When selecting between steel cables and synthetic ropes for winches, consider that steel cables provide superior strength and durability for heavy loads, while synthetic ropes are lighter, more flexible, and safer in case of a breakage. Your choice should depend on the specific requirements of your application and the conditions in which the winch will operate.